Case Study

$250,000 in Annual Savings for Southeast Veterans Hospitals with Comprehensive Energy Conservation Solutions

SMI Impact

Total savings in excess of $250,000 per year

Leak repair for improved system health and safety with savings in excess of 4,000,000 gallons of water per year

Estimated 160,590 lbs of steam saved per year with installation of pressure motive pumps and Improved control of perimeter heating units

Estimated savings of $53,661 with condensate heat recovery

Estimated savings of $75,862 with insulation upgrades

Steam Management, Inc. was contracted by an ESCO to design, bid, and execute turnkey installations of multiple ECMs across veterans' hospitals in the Southeast, including locations in Atlanta, Birmingham, Montgomery, Tuscaloosa, and Tuskegee.

Customer

The ESCO wanted to include significant thermal savings for this project. Our challenge was that the hospital network had an existing steam trap monitoring system with preventative maintenance program. The hospital had also recently installed new pipe and equipment insulation throughout most mechanical spaces. Steam Management was tasked with finding creative solutions for the ESCO to include in its EPC.

Problems

Existing hot water distribution system design did not allow condensate to be returned to the boiler, because the discharge from the domestic hot water heaters is too low to enter the boiler condensate return tank. The result being that the client was either discharging condensate to a drain unnecessarily due to equipment failure or pumping recoverable energy in condensate back to the utility. Additionally, because the existing condensate return pump was not functioning properly, it was running continuously and wasting electricity.

Steam pressure is maintained at a level that is not needed for most of the days throughout the year resulting in decreased efficiency

Facility has full-time, year-round steam demand for domestic hot water, building heat, and sterilization.

Leaking steam distribution piping

Uninsulated steam, condensate and HW piping across multiple buildings

Condensate Pump System Replacement

Steam Piping Insulation

Pressure Motive Pump Pressure Regulator

Condensate Heat Recovery

Digital PRV

Scope of Work

Leak Repairs

Chiller Plant Improvements

HVAC Upgrades

Thermostatic Radiator Valves

Survey, design and develop multiple scopes of work

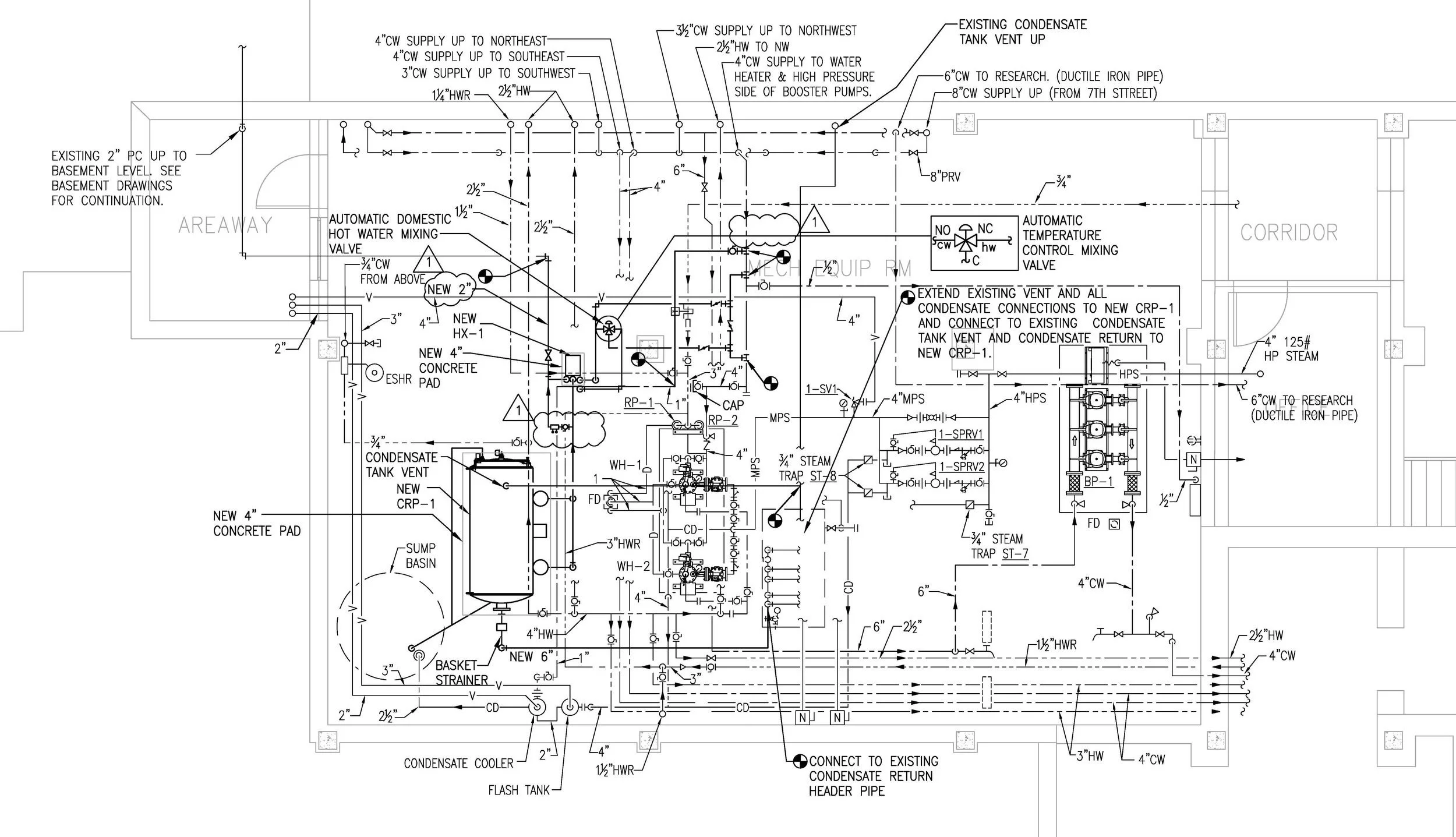

Submit stamped engineered drawings with equipment schedules for project approval

Prepare product submittal packages for project approval

Prepare work and safety plans with JHA for project approval

Manage material purchasing and handling on site across 5 VAMC facilities

Manage all subcontracted labor for turnkey installation

Work with facility and building managers for site access and utility shutdowns

On-site project management by SMI personnel

Conduct start-up and weekly safety meetings

Installation of 655.5 linear feet of pipe insulation, 198 fittings, and 20 RICs across the hospital campus

installation of a new fully functional steam condensate return system including, electrical, controls, receiver tank, pumps, tube and shell heat exchange, insulation and appurtenances.

Installation of 33 thermostatic radiator valves across six high traffic buildings

Installation of five pressure motive pumps

Pre & post M&V data for all installed components

Complete project commissioning, punch list and sign-off walk throughs

Provide site training with videographer

Key Actions

Schedule an Assessment of Your Facility

info@steammgt.com

1-800-731-0131

One Lincoln Street, Suite 2400

Boston, MA 02111