Case Study

Supporting a Utility Energy Service Contract at San Francisco VA Medical Center: SMI Delivers Steam System Performance Upgrades

SMI Impact

Estimated 5,764 (Mlb/yr) and $46,108 of savings from steam traps annually

Estimated 10,365 MMBtu/yr energy conserved annually from insulation upgrades

Expanded monitoring with real-time data on steam traps, enabling proactive maintenance.

Improved safety by reducing high-surface temperature exposure and mitigating system inefficiencies.

Supported the ESCOs UESC objectives by delivering long-term, measurable performance improvements.

Steam Management, Inc. (SMI) was engaged by an ESCO to conduct a comprehensive steam system assessment at the VISN 21 San Francisco VA Medical Center. The goal of the assessment was to develop a detailed scope of work for insulating exposed steam and hot water piping, addressing steam trap failures, and identifying additional system improvement opportunities. Based on the findings, SMI was selected to implement the insulation upgrades, steam trap replacements, and steam trap monitoring system expansion as part of the Utility Energy Service Contract (UESC). The project aimed to reduce energy consumption, lower operation and maintenance costs, and enhance overall system resiliency.

Customer

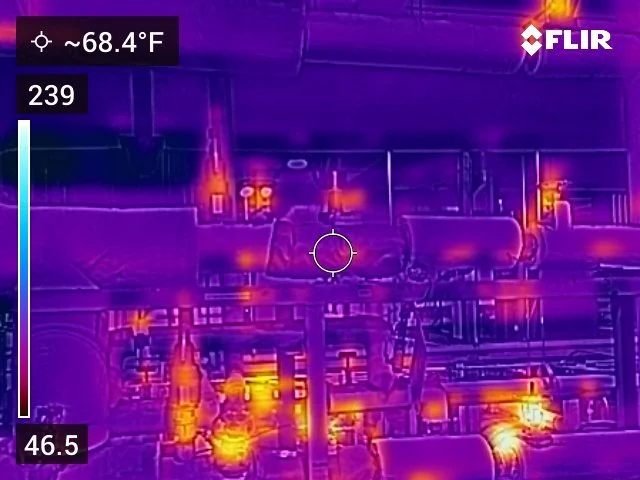

The assessment revealed a 41% failure rate among the 250 steam traps tested, with many located in confined, difficult-to-access areas that complicated maintenance and inspections. In addition, the VA Directive restricted the use of cast iron or malleable materials in steam trap valve train components, requiring careful material selection for all replacements. Throughout the campus, significant thermal losses were observed due to uninsulated piping, valves, tanks, and other fittings. These inefficiencies were compounded by monitoring gaps in the existing Armstrong SteamEye system, which left portions of the steam network without real-time visibility or proactive maintenance capabilities.

Conditions

SMI executed the following turnkey scopes across 15 campus buildings:

Full Steam System Audit

Performed a comprehensive audit of the steam system, including 15 buildings and associated steam tunnels.

Tested and tagged steam traps using ultrasonic and infrared testing.

Documented trap locations, applications, operating pressures, and failure modes.

Developed engineering calculations and savings models to support ECM prioritization by quantifying energy losses and project savings.

Provided detailed reporting, mapping, and field data to inform system upgrades.

Steam Trap Replacements

Replaced failed steam traps with VA-compliant components (non-cast iron/malleable materials).

Solution

Steam Trap Monitoring System Expansion

Retro-commissioned 64 existing SteamEye monitors

Installed 58 new monitors to expand coverage across previously unmonitored steam traps.

Integrated new monitors into the existing Armstrong SteamEye Gateway, enabling centralized visibility of trap status from a secure campus location.

Steam System Insulation Improvements

Installed 848 linear feet of new conventional pipe insulation.

Fabricated and installed 132 removable insulation covers on valves, tanks, and other high-temperature equipment.

Improved personnel safety and reduced energy losses across the steam and hot water distribution systems.

Schedule an Assessment of Your Facility

info@steammgt.com

1-800-731-0131